CO₂ measurement is essential for complying with environmental regulations, ensuring energy efficiency, and reducing the carbon footprint in industry. From high-precision sensors to energy management systems (EMS), measuring and calculating carbon dioxide emissions allows Mexican companies to optimize processes, make data-driven decisions, and move toward more sustainable and competitive operations.

CO₂ measurement is a key indicator for the energy and electricity industry. It is not just a matter of complying with regulations, but of integrating the carbon footprint into companies’ financial and operational decisions. In Mexico, where the sustainability and energy efficiency agenda is a fundamental pillar, monitoring and managing CO₂ has also become a strategic priority.

For this reason, there are several technologies and devices that companies can use to quantify emissions savings in real time, visualize financial savings, and make better decisions to optimize their energy consumption. Depending on the application or environment in which CO2 is to be measured, different methods are used.

What is CO2 measurement?

CO2 measurement, in an industrial context, is the process of quantifying the concentration of this gas in the atmosphere or in production processes. Unlike the carbon footprint, which is an estimate of total emissions, real-time CO2 measurement provides accurate data that aids energy management and decision-making in environments where efficiency and safety are critical.

In Mexico, the General Law on Climate Change and the National Emissions Registry (RENE) establish the regulatory framework for industries to report their footprint and design mitigation strategies.

Methods and technologies for measuring CO2

The choice of CO2 measurement method or equipment depends on the specific application, the required accuracy, and the environmental conditions. For CO2 measurement in offices or some companies, non-dispersive infrared (NDIR) devices are used as they are the most common and reliable technology. There are also electrochemical sensors to assess air quality or toxic gases in the environment, although they are more sensitive to contamination and tend to have a shorter lifespan.

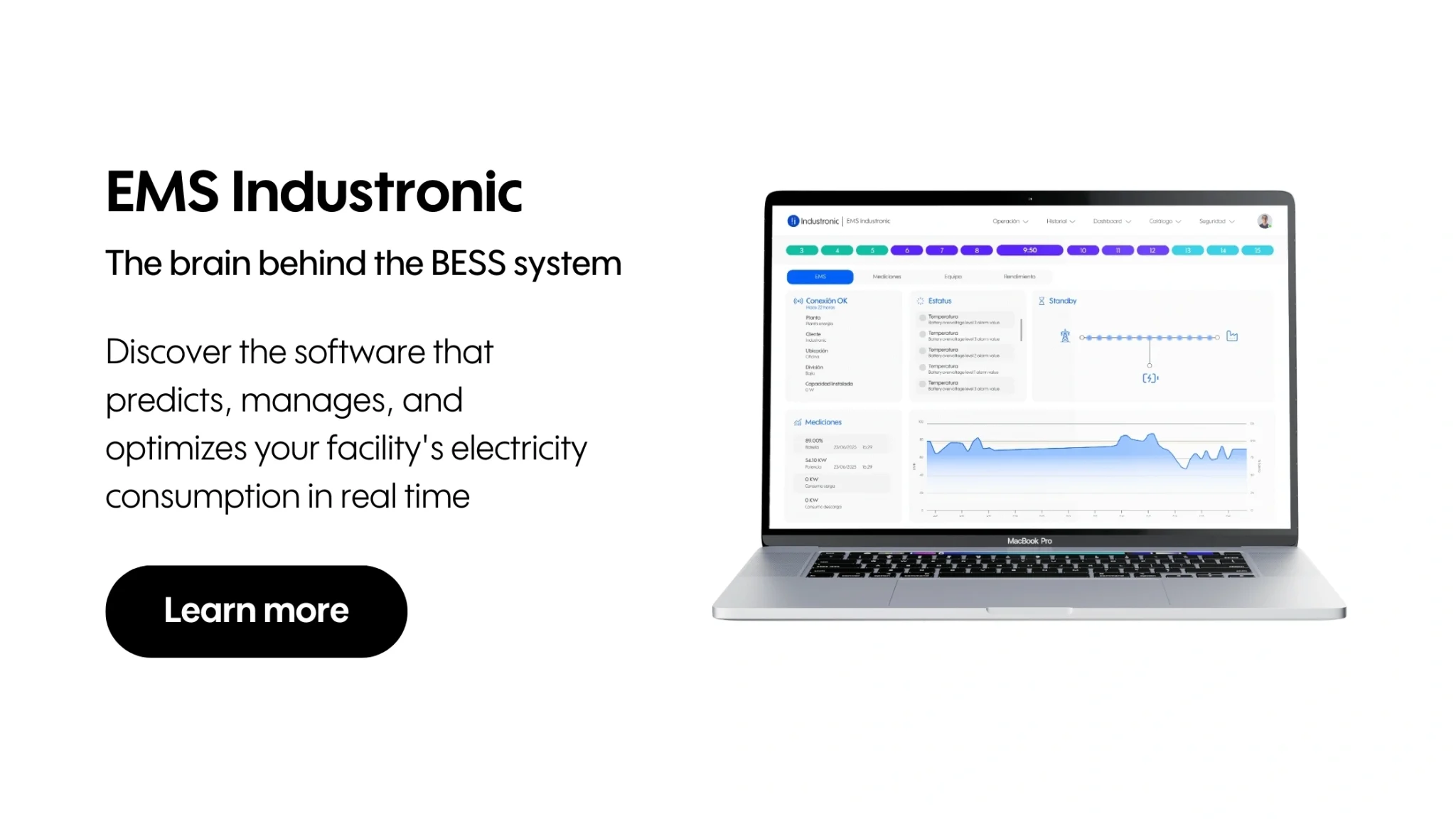

For companies with industrial processes that require higher electricity consumption, there are advanced technologies such as Energy Management Systems (EMS). These systems do not directly measure CO₂, but they do allow it to be calculated based on energy consumption, integrating software, hardware, and methodologies to monitor, control, and optimize energy.

Through their online platform, the most advanced EMS (including Industronic’s EMS for BESS) offer real-time sustainability reports. These reports calculate the CO2 equivalent that is not emitted thanks to smart energy consumption. They also visually show CO2 savings, carbon reduction, and trees saved, providing a complete snapshot of the electrical management of a production or corporate plant.

Read also: BESS for factories in Mexico: How to optimize energy management and reduce costs?

The importance of measuring CO2 in industry

Both for the optimization of industrial processes and for regulatory compliance in Mexico, measuring CO2 is important because it impacts factors such as:

- Energy and economic efficiency: measuring CO2 in real time allows inefficient processes to be identified, such as oversized ventilation systems or equipment that consumes more energy than necessary. Areas for improvement are also evaluated, such as replacing diesel boilers with natural gas or converting processes. By detecting and correcting these types of situations, the associated cost reduction is significant and, with it, the economic improvement in industries is greater.

- Sustainability and regulatory compliance: Rigorous CO2 measurement enables auditable, comparable, and ESG-linked reporting. It should be remembered that, in Mexico, as a signatory to the Paris Agreement, accurate data must be provided to comply with regulations such as those of the Ministry of the Environment and Natural Resources (SEMARNAT) and to obtain sustainability certifications that improve reputation and access to markets.

- Technological innovation and safety: by integrating intelligent systems with EMS, CO2 measurement in offices or industrial companies is no longer a passive process and becomes an input for real-time decision-making. In addition, constant monitoring of CO2 levels is a critical preventive measure to ensure a safe working environment, protecting employees from exposure to toxic levels.

Applications of CO2 measurement

Thanks to the benefits of CO2 measurement, this practice is applicable in sectors and processes such as:

- Heating, ventilation, and air conditioning (HVAC) systems: In large buildings and factories, measuring CO2 optimizes ventilation. When levels rise, the system can increase the flow of fresh air to maintain a safe environment.

- Combustion processes: In boilers, industrial furnaces, and power plants, measuring CO2 in exhaust gases is crucial to ensuring that fuel is burned efficiently, minimizing emissions and maximizing energy production.

- BESS (Battery Energy Storage Systems) management: In a BESS with an Energy Management System (EMS), CO2 measurement is a control parameter, as the EMS can use CO2 data to decide when to charge or discharge batteries, prioritizing energy from renewable sources (which do not emit CO2) over that from the power grid, thereby reducing the carbon footprint of the customer’s operations.

Frequently asked questions about CO2 measurement

What equipment is used to measure CO2?

Non-dispersive infrared (NDIR) sensors are mainly used to measure CO₂, as they are common in offices and enclosed spaces due to their accuracy and reliability. In the industrial sector, in addition to direct sensors, Energy Management Systems (EMS) are used, which do not physically measure CO₂, but calculate the equivalent emitted or avoided based on energy consumption, generating real-time sustainability reports.

What CO₂ levels are safe?

Generally, in indoor environments, levels range from 400–1000 parts per million (ppm). For offices or work classrooms, 700 to 800 ppm is considered adequate. In industry, the limits depend on occupational safety regulations, but for footprint purposes, it is measured in equivalent tons and should not exceed 5000 ppm for 8 hours.

How does CO₂ measurement help save energy?

By measuring CO₂, companies identify inefficiencies in ventilation, combustion, electricity consumption, and other industrial processes. This reduces waste and costs. In addition, with an Energy Management System (EMS), this information is converted into real-time reports that suggest when and how to optimize energy use, maximizing time and money savings while reducing the carbon footprint.

How often should CO₂ be monitored?

The frequency of CO2 monitoring depends on the application: in enclosed spaces, continuous monitoring or frequent readings are recommended to ensure safety, while corporate inventories are usually done annually. However, with an Energy Management System (EMS), monitoring can be constant and in real time, allowing for immediate adjustments, energy savings, and a reduced carbon footprint.

Consult our experts for the best option to protect your electrical installation

Our team will provide you with personalized advice